My rifle is done. And it looks great. To me anyway. I don’t remember where I saw the Hogue OverMolded furniture first but I do remember that I was immediately intrigued by the “Lava” colored option. It’s unusual and unique and I have heard it characterized more like a brick color than lava and I think that’s an apt description. I originally bought the buttstock and pistol grip set with the intention of installing it on my S&W 15-22. Wanted to spice up my plinker a bit. I changed my mind almost immediately after installing it. I just didn’t like the look without a matching handguard. It just seemed unbalanced and my OCD nature wasn’t going to stand for it. The fit and finish of the pistol grip and butt stock is outstanding though. The mil-spec version of the buttstock fits snugly on the buffer tube and has very limited wiggle. It can be a little stiff when shortening or lengthening the stock but that doesn’t bother me. The OverMolded material on the buttpad and cheek rest are comfortable and have an agreeable texture. The pistol grip fits my hand well and again the texture and feel of the OverMolded material is comfortable and practical. The grip is a bit larger than a typical pistol grip but still fits my not-overly large hands well.

I liked the set so much that I bought another in OD green to put on my Just Right Carbine. In this case I overcame my lack of a matching handguard by installing matching rail covers and a foregrip. It turned in my opinion the fairly plain and drab appearance of the Just Right Carbine into something more interesting to look at. You can see my review of the Just Right Carbine here. You may also notice that the Burris AR-332 scope that I had on the JR Carbine has found a new home on my new AR. The Burris AR-332 magnified red dot is designed for a .223 AR platform rifle. It was quite obviously overkill for the 9mm carbine.

I liked the set so much that I bought another in OD green to put on my Just Right Carbine. In this case I overcame my lack of a matching handguard by installing matching rail covers and a foregrip. It turned in my opinion the fairly plain and drab appearance of the Just Right Carbine into something more interesting to look at. You can see my review of the Just Right Carbine here. You may also notice that the Burris AR-332 scope that I had on the JR Carbine has found a new home on my new AR. The Burris AR-332 magnified red dot is designed for a .223 AR platform rifle. It was quite obviously overkill for the 9mm carbine.

The Hogue OverMolded free float extended forend is the primary purpose of this review though. Both the buttstock and the pistol grip are very typical of other options on the market. The only difference being the OverMolded material that Hogue uses. The forend though is especially interesting and it has some very easily identified pros and cons.

Let’s star with the pros:

- Very unique look – it’s quite simply an unusual look for an AR-15. I suspect there are

as many people who hate the look as like it. It’s very in your face and eye catching.

as many people who hate the look as like it. It’s very in your face and eye catching. - Fit & Finish – the handguard feels good in the hands and is has a relatively thin profile that makes it comfortable and easy to handle. The material’s texture is tacky enough to feel secure without being remotely abrasive. Once installed the forend is rock solid and the finish reminds me of the fine leather material on the inside of a sports car. Nothing feels remotely cheap about this handguard.

- Adequate space for accessories and rails – Hogue makes several versions of this handguard and this version, the “extended” version, has the best options for installing accessories.

To install rails you simply screw short sections of rails into the handguard with the hardware included. Hogue includes a good selection of rails and accessories with the forend. I have installed a rail for a backup red dot at 45 degrees, a couple of barricade stops, a front sling swivel and a quick release button.

To install rails you simply screw short sections of rails into the handguard with the hardware included. Hogue includes a good selection of rails and accessories with the forend. I have installed a rail for a backup red dot at 45 degrees, a couple of barricade stops, a front sling swivel and a quick release button.

Now for the cons:

- It ain’t cheap – I bought the handguard for about $200. Not cheap by any stretch but not outrageously expensive in comparison to other options either.

- It’s slim profile limits what gas blocks can be used – this is probably my biggest problem with the hanguard, it’s slim profile doesn’t allow much space for gas blocks. I really wanted to install an adjustable gas block on this rifle. I believe it is possible to find a small enough adjustable gas block with a set screw but the design of the handguard doesn’t allow practical access to that set screw. The DPMS low-profile gas block I used barely fits and it appears to just slightly contact the top inside of the handguard. I have a real problem with this because this is of course a “free float handguard,” the whole idea being to minimize the forces that can act on the barrel.

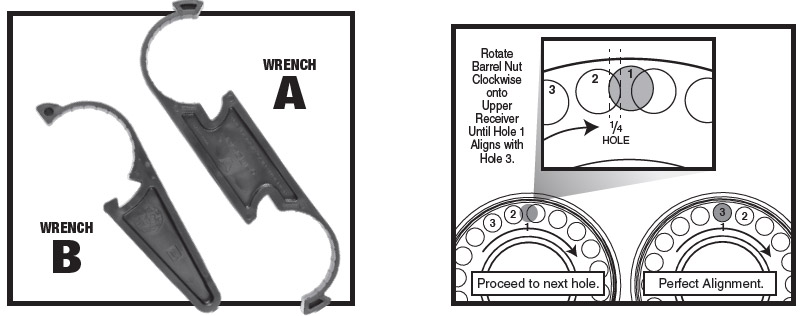

- It has an unusual barrel nut system –

the Hogue OverMolded free float extended forend has a unique barrel nut system that is supposed to be self setting in regards to torquing down the barrel. It essentially works like any other barrel nut in terms of lining up the gas tube holes but is somewhat arbitrary in terms of how much to torque it down. The supplied wrench is usable but difficult to manipulate and I chose instead to use a strap wrench instead which worked much better. Here’s the real problem: I “think” I have the barrel nut installed correctly according to Hogue’s directions and I “think” it’s torqued down adequately but honestly I’m not “sure.” As a first time builder I would prefer to be sure. I simply don’t have enough experience to feel entirely confident in this install. I will be keeping a close eye on the barrel nut to make sure it has not loosened. I did take steps to make sure to “season” and lubricate the threads in the hope that once installed the barrel nut would remain tight.

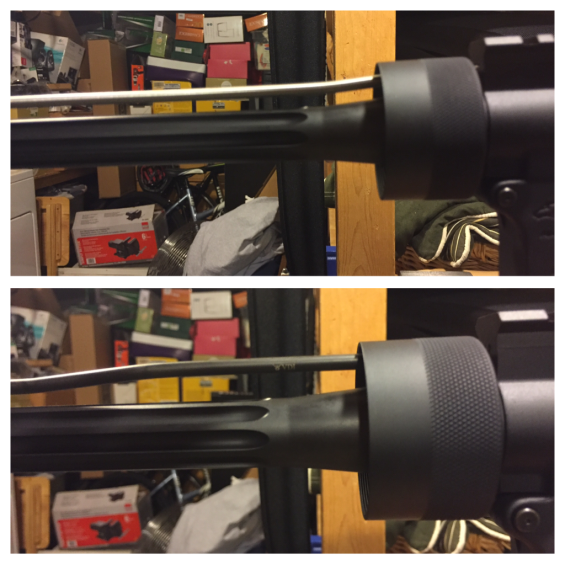

the Hogue OverMolded free float extended forend has a unique barrel nut system that is supposed to be self setting in regards to torquing down the barrel. It essentially works like any other barrel nut in terms of lining up the gas tube holes but is somewhat arbitrary in terms of how much to torque it down. The supplied wrench is usable but difficult to manipulate and I chose instead to use a strap wrench instead which worked much better. Here’s the real problem: I “think” I have the barrel nut installed correctly according to Hogue’s directions and I “think” it’s torqued down adequately but honestly I’m not “sure.” As a first time builder I would prefer to be sure. I simply don’t have enough experience to feel entirely confident in this install. I will be keeping a close eye on the barrel nut to make sure it has not loosened. I did take steps to make sure to “season” and lubricate the threads in the hope that once installed the barrel nut would remain tight. - It requires a custom gas tube – Okay. Here is the real issue when it comes to this forend. It essentially requires a custom bent gas tube. I did know this going in but I didn’t really have any idea what a pain in the ass this would be. Hogue does sell a custom gas tube but it can only be used with a couple of their forends and only in a carbine gas setup. Frankly it’s a bit confusing. And annoying. I bought the Hogue pre-bent tube to use as a template for bending my own. Here are a couple of pictures that demonstrate the difference between the Hogue pre-bent carbine length tube and the normal mid-length tube.

Hogue Pre-Bent Carbine Gas Tube (top) Compared to Normal Mid-Length Gas Tube (bottom)

Pretty dramatic difference. Clearly designed to provide additional clearance between the gas tube and the forend where it screws into the barrel nut. Of course it’s not as simple as just making an additional bend in the mid-length gas tube where it exits the barrel nut, that would throw off the tubes overall alignment between the gas hole in the upper receiver and gas block. First I had to straighten the tube as best I could and then put in a new bend. It’s doable. I did it. With my first tube in fact because I bought an extra. I tried it first with my spare which was stainless steel unlike the black tube I ultimately intended to use. I stuck with the stainless steel because frankly I wasn’t interested in doing it again. Ever frankly.

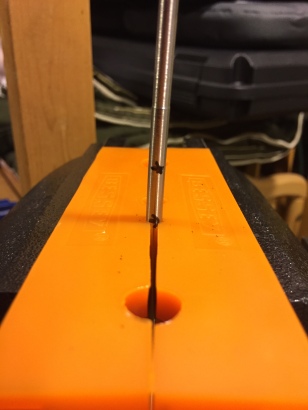

Here is how I did it: I marked on the tube where it needed to be straightened and bent and then inserted it into a vice and slowly began to bend it. I used a vise pad that had holes that fairly closely matched the diameter of the gas tube. I must have pulled it out and put it back in half a hundred times. I wanted to make sure I didn’t kink the tube and therefore effect its overall airflow. It was slow and tedious. I have no doubt that there are better ways to go about doing this. Including buying a tool specific to bend tubing. I didn’t however want to buy another tool that would likely be used only once for a unique job. I really think if Hogue is going to sell a handguard that requires a custom gas tube than they should manufacture them themselves. Hogue isn’t a small company, they manufacture a variety of products. I don’t think its unreasonable to provide or sell a compatible gas tube for their forend. I’d have to have a pretty compelling reason to go through this process again.

Here is how I did it: I marked on the tube where it needed to be straightened and bent and then inserted it into a vice and slowly began to bend it. I used a vise pad that had holes that fairly closely matched the diameter of the gas tube. I must have pulled it out and put it back in half a hundred times. I wanted to make sure I didn’t kink the tube and therefore effect its overall airflow. It was slow and tedious. I have no doubt that there are better ways to go about doing this. Including buying a tool specific to bend tubing. I didn’t however want to buy another tool that would likely be used only once for a unique job. I really think if Hogue is going to sell a handguard that requires a custom gas tube than they should manufacture them themselves. Hogue isn’t a small company, they manufacture a variety of products. I don’t think its unreasonable to provide or sell a compatible gas tube for their forend. I’d have to have a pretty compelling reason to go through this process again.

And there you have it. It may seem like the cons outweigh the pros but I think time will be the true measure. I like the handguard. I like it a lot. More than I thought I would in fact. It feels good and fits my hand right. I think it’s the most comfortable handguard between all of my AR’s. It feels tight and solid. In fact, the whole rifle feels rock solid. In part 3 I will review how the rifle performs. I have had the opportunity to shoot it but primarily to sight in the optics and break it in. Hoping to put it through its paces soon.

JD

Categories: Firearm & Gear Reviews

Thank you for the review. I was just looking into the Hogue Overmolded Handguard and you confirmed what I had thought. I love the look and function but the gas tube thing is definitely a negative. Also, the other negative is that there is no sling or bipod attachment. As much as I want this handguard those two things are keeping me from it.

LikeLike

Yep. The gas tube is likely the deal breaker for me if I were considering getting another one. The sling or bipod attachments can be overcome though, depends on the forearm you choose. Mine in the review has quite a few places that a swivel stud can be installed.

LikeLike

Thank you for the informative review. I am in the same shoes – bought full kit of red lava (including extended forend) for my build. I’ve decided to leave ithe gas tube rebending and properly torque the forend to the gunsmith. It is my first build and I want to avoid any potential problems with that. It is realy the shame Houge doesn’t provide properly bended tube – in my case rifle lenght. As far as I know mid-lenght Hogue gas tubes are now available and only stainless.

LikeLike